Parts & Accessories

Detection Devices

KNOW WHAT YOU’RE LOOKING FOR?

Refri-Shield™ Level Gauge

ELECTRONIC | MAXIMUM WORKING PRESSURE: 700 PSIG

Features

This electronic level gauge is the introductory product to the Refri-Shield™ line of level-detection components. Featuring an electronic readout and bubble-level for installation, this device can be serviced and replaced by two set screws without pumping the system down. The Rotolock sight glass housing utilizes a PTFE gasket for a superior seal—minimizing the leak potential.

- Designed for use in horizontal vessels

- 1 3/4″ Rotolock sight glass design

- Watertight electronics enclosure made of DuPont Zytel glass-reinforced polymers

- 12 ft cable

- 12V AC or DC

DC accepted range: 11.5V—14V

AC accepted range: 10V—14V - Amp draw: 12V supply

70mA—100mA (depending on relay state) - 12V common

Relay common - 0.5V out +/- 0.1V

Minimum accepted load: 100 ohms - 4—20mA out

Max load for full 20mA: 400 ohms - Dry Contact Relay—set at 20%

Relay contact rating: 2 amps - Electronic Operating Temperature

-40°C to 85°C (-40°F to 185°F) - Factory calibrated

- Pressure-boundary components listed in accordance with UL-207

- Patent pending

| Catalog Number* | Vessel OD | Swing Radius |

| RSG-8E | 8 5/8" | 4 3/4" |

| RSG-10E | 10 3/4" | 6" |

| RSG-12E | 12 3/4" | 7" |

| RSG-14E | 14" | 8 1/2" |

| RSG-16E | 16" | 9 1/2" |

| RSG-18E | 18" | 10 1/2" |

| RSG-20E | 20" | 11 1/2" |

| RSG-24E | 24" | 13 1/2" |

*Add “R” for four-bolt retrofit models (Ex: RSG-8ER)

Replacement Electronic Housing part number: RSG-1HE

ROTOLOCK CONNECTION

RSG series level gauges utilize a 1 3/4″ Rotolock connection with PTFE gasket on new receiver installations for a superior seal.

FOUR-BOLT RETROFIT

Retrofit assemblies for existing four-bolt flange receivers are also available. Retrofit kits include flange plate, gaskets, and bolts for installation.

Refri-Shield™ Level Gauge

Mechanical | MAXIMUM WORKING PRESSURE: 700 PSIG

Features

This mechanical level gauge is one of the introductory products to the Refri-Shield™ line of level-detection components.

The Rotolock sign glass housing utilizes a PTFE gasket for a superior seal, minimizing leak potential.

- Designed for use in horizontal vessels

- 1 3/4″ Rotolock design

- Sight glass with easy-to-read liquid level indicator

- Pressure-boundary components listed in accordance with UL-207

- Blank (non-electronic) housing with bubble-level included for installation alignment purposes

- Conversion kits available for upgrade to electronic model (part number RSG-1HE

| Catalog Number* | Vessel OD | Swing Radius |

| RSG-8 | 8 5/8" | 4 3/4" |

| RSG-10 | 10 3/4" | 6" |

| RSG-12 | 12 3/4" | 7" |

| RSG-14 | 14" | 8 1/2" |

| RSG-16 | 16" | 9 1/2" |

| RSG-18 | 18" | 10 1/2" |

| RSG-20 | 20" | 11 1/2" |

| RSG-24 | 24" | 13 1/2" |

*Add “R” for four-bolt retrofit models (Ex: RSG-8R)

Replacement Alignment Housing part number: RSG-1H

ROTOLOCK CONNECTION

RSG series level gauges utilize a 1 3/4″ Rotolock connection with PTFE gasket on new receiver installations for a superior seal.

FOUR-BOLT RETROFIT

Retrofit assemblies for existing four-bolt flange receivers are also available. Retrofit kits include flange plate, gaskets, and bolts for installation.

Refri-Shield™ RDP-01

Differential Pressure Monitor

MAXIMUM WORKING PRESSURE: 667 PSIG

Features

The RDP-01 Differential Pressure Monitor is part of the Refri-Shield™ line of system monitoring products.

When the filter element of a coalescing oil separator is contaminated, it negatively affects performance and efficiency—of the oil separator itself, and of the entire system. A differential pressure monitor is used to monitor, both visually and electronically, when the filter is contaminated and needs replaced.

The Refri-Sheild™ RDP-01 features a multicolored LED readout indicating pressure range and an analog output for precise pressure monitoring. The device’s

case is both dust and weather resistant and comes equipped with 6-foot pressure-transducer cables and a 6-foot power cable, allowing for significant versatility in

its placement.

SPECIFICATIONS

- Power supply: 10—24V AC or DC

6′ power cable included (24 AWG) - Analog output for PSID monitoring

0.5—4.5V at 0—20 PSID

Min. accepted load: 500 ohms

± 0.4 PSID accuracy - Amp Draw: 30mA

- Operating Temperature:

Electronics Enclosure: -40°F to 175°F

Pressure Transducers: -40°F to 257°F - Heavy-Duty Pressure Transducers

- Brass Housing

- Port: 7/16—20 UNF 1/4″ 45° Flare Female Schrader (SAE J512)

- Temperature-compensated

- 6′ cable included

- Max. Operating Pressure: 667 PSIG

Overpressure: 1,000 PSIG

- Mounting screws included

- Weather and dust-resistant case

- Multicolor LEDs for quick visual monitoring

- GREEN: 0—8 PSID

- YELLOW: 8—12 PSID

- RED: >12 PSID

- Blinking RED indicates overpressure:

- If pressure falls below overpressure before 20 seconds have elapsed, overpressure indicator will turn off.

- If overpressure continues for more than 20 consecutive seconds, overpressure indicator remains on until reset.

- During overpressure, device continues to monitor PSID

- Overpressure indicator reset button on front of case

- Blinking YELLOW indicates disconnected transducer

- Factory Calibrated using a Patent Pending process

Refri-Shield™ RDP-01T

Differential Pressure Monitor

FOR TRANSCRITICAL CO2 | MAXIMUM WORKING PRESSURE: 2175 PSIG

Features

The RDP-01T Differential Pressure Monitor is part of the Refri-Shield™ line of system monitoring products. This model features transducers designed for use with CO2 systems at transcritical pressures.

When the filter element of a coalescing oil separator is contaminated, it negatively affects performance and efficiency—of the oil separator itself, and of the entire system. A differential pressure monitor is used to monitor, both visually and electronically, when the filter is contaminated and needs replaced.

The Refri-Sheild™ RDP-01T features a multicolored LED readout indicating pressure range and an analog output for precise pressure monitoring. The device’s

case is both dust and weather resistant and comes equipped with 6-foot pressure-transducer cables and a 6-foot power cable, allowing for significant versatility in

its placement.

SPECIFICATIONS

- Power supply: 10—24V AC or DC

6′ power cable included (24 AWG) - Analog output for PSID monitoring

0.5—4.5V at 0—20 PSID

Min. accepted load: 500 ohms

± 2 PSID accuracy - Amp Draw: <50 mA

- Operating Temperature:

Electronics Ambient: -40°F to 175°F

Transducers Ambient: -22°F to 185°F

Transducers Refrigerant: -40°F to 275°F - Heavy-Duty Pressure Transducers

- Stainless steel 316 housing and 304 pressure connection

- Port: 1/4—18 NPT

- Temperature-compensated

- 6′ cable included

- Max. Operating Pressure: 2175 PSIG

- Mounting screws included

- Weather and dust-resistant case

- Multicolor LEDs for quick visual monitoring

- GREEN: 0—8 PSID

- YELLOW: 8—12 PSID

- RED: >12 PSID

- Blinking RED indicates overpressure:

- If pressure falls below overpressure before 20 seconds have elapsed, overpressure indicator will turn off.

- If overpressure continues for more than 20 consecutive seconds, overpressure indicator remains on until reset.

- During overpressure, device continues to monitor PSID

- Overpressure indicator reset button on front of case

- Blinking YELLOW indicates disconnected transducer

- Factory Calibrated using a Patent Pending process

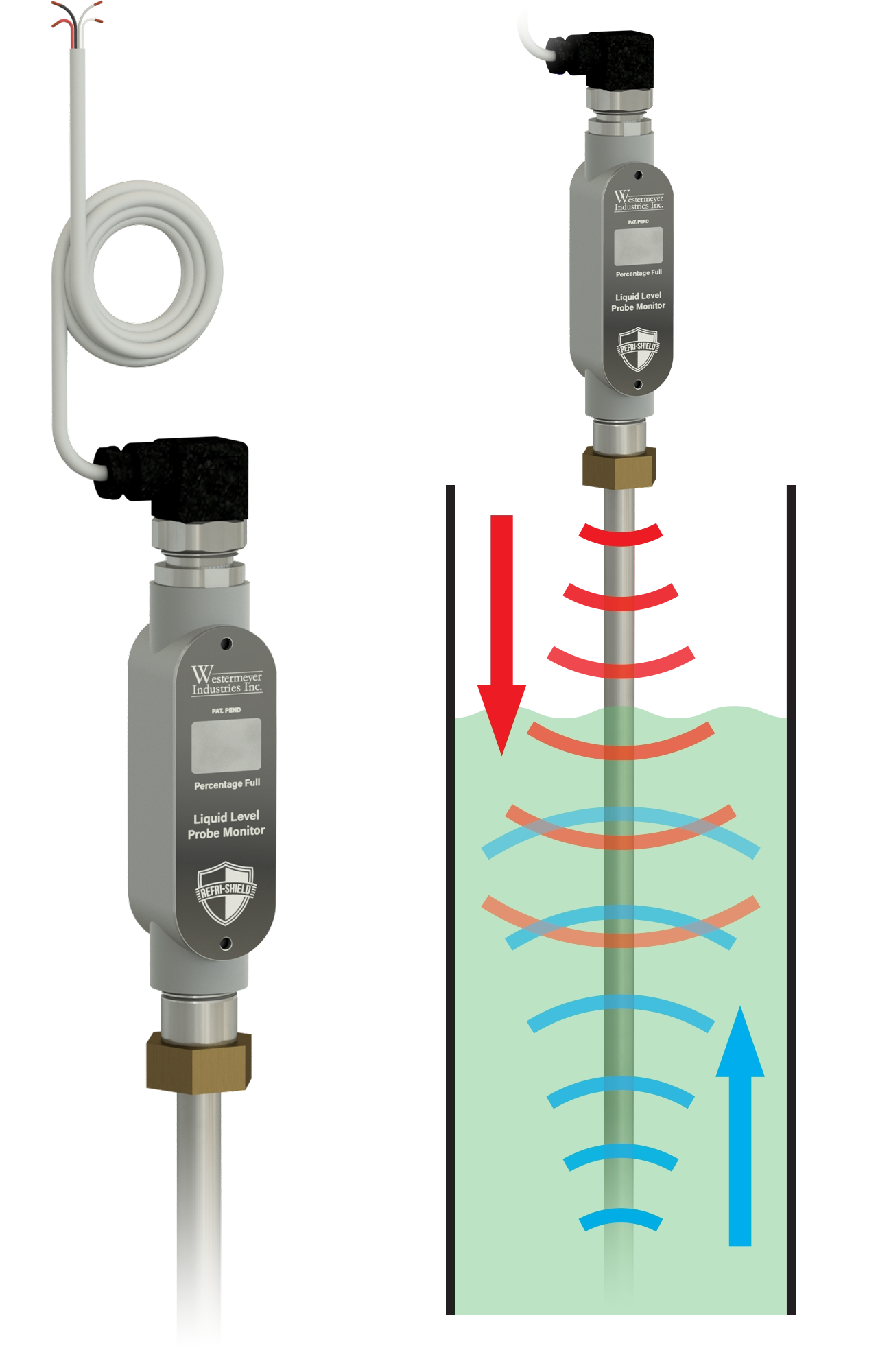

LeveL Probe

MAXIMUM WORKING PRESSURE: 1,000 PSIG

Features

The “RLP Series” Level Probe is a new addition to the Refri-Shield™ line of system monitoring products.

Level probes have long been used for monitoring fluid-level inside of pressure vessels, most utilizing dielectrics to detect the specific level. These “legacy products” create complexity in the ever-changing refrigerant conversions. With our new “RLPSeries level probes, we have developed a product which no longer requires fluid-specific calibration. Based on proven technology – Time Domain Reflectometry (TDR), whether you’re using refrigerant or oil, this one model can provide accurate readings, without the need of field calibration.

- 12-24v AC or DC supply

- 1-6v DC output

- Ambient temperature range:

-40°F (-40°C) to 158°F (70°C) - Refrigerant temperature range:

-40°F (-40°C) to 158F (70°C) - 12-foot DIN connector cable

Ordering

Westermeyer Industries custom manufactures every probe to your specifications. To order, state the required length in inches as the part number with the appropriate suffix to designate optional Rotolock and/or display.

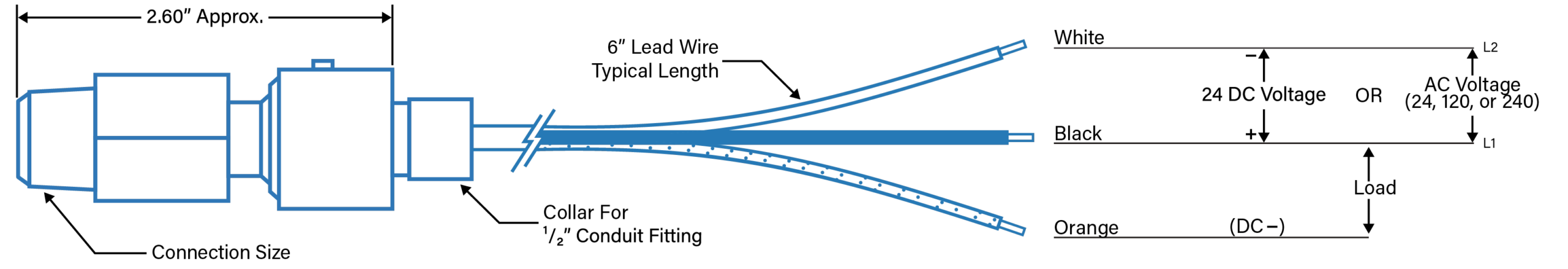

Level Transducer Probe

MAXIMUM WORKING PRESSURE: 1,000 PSIG

Features

Level transducer probes (LP) are made for monitoring refrigerant levels in vertical or horizontal receivers. The probe operates with capacitance to provide a continuous level reading. The electronic circuit provides an analog signal that is proportional to the refrigerant level. This signal is provided as a 0–5V DC output commonly used with supermarket rack controllers, PLCs, and other types of control devices that will accept the input.

The probe is threaded directly into the receiver by the use of a 3/4″ NPT coupling or Rotolock. The probe has no moving parts and uses 24V DC as the input voltage.

- 10–24V DC supply voltage

0–5V DC output voltage

or

4–20mA output voltage (for vessels up to 12″) - Ambient temperature range:

-40°F (-40°C) to 158°F (70°C)

Refrigerant temperature range:

-40°F (-40°C) to 158°F (70°C) - 3/4″ NPT or 1 1/4″ Rotolock connection

- 12-foot DIN connector cable

- Optional display available

Ordering

Westermeyer Industries custom manufactures every probe to your specifications. To order, state the required length in inches as the part number with the appropriate suffix to designate optional Rotolock and/or display.

Liquid Level Switches

MAXIMUM WORKING PRESSURE: 1000 PSIG

Features

The LS liquid level switch is a highly reliable method of detecting fluid levels. Solid-state construction ensures many years of trouble-free operation. The hermetically sealed sight glass provides high working pressures without leakage. Liquid levels are optically detected through the sight glass, for fluids as clear as water or as dirty as crude oil.

The switch must be installed horizontally with at least 2″ of distance between it and the vessel wall or pipe. Line voltage is wired directly to the switch, removing the need for step-down transformers. A 1/2″ conduit box is provided for the mounting of a junction box. Two thread models are available for various applications.

- Body made of 1 1/8″ hex nickel plate Steel

- Solid-state switching

- Serviceable without loss of fluid

- UL listed, file number E141577

- Switch rated at over 1 million cycles

- Non-invasive liquid sensing

- Suitable for refrigerants and other industrial fluids non-corrosive to steel and glass.

![]()

| Catalog Number* | Conn. Size | Voltage | Resistive Rating | Contacts w/ Liquid Present | Wire Color | Repl. Module | Fluid Temp. | |

| 60/80 Hz | AMP | Min | Max | |||||

| LS-120 | 1/2" NPT | 120V | 0.5 | Closed | Yellow | 180-001 | 0°F | 200°F |

| LS-120A | 1/2" NPT | 120V | 0.5 | Open | Yellow | 180-002 | 0°F | 200°F |

| LS-120-W | 3/4"-16 UNJF-3A | 120V | 0.5 | Closed | Yellow | 180-001 | 0°F | 200°F |

| LS-120A-W | 3/4"-16 UNJF-3A | 120V | 0.5 | Open | Yellow | 180-002 | 0°F | 200°F |

| LS-240 | 1/2" NPT | 208/240V | 0.25 | Closed | Red | 180-003 | 0°F | 200°F |

| LS-240A | 1/2" NPT | 208/240V | 0.25 | Open | Red | 180-004 | 0°F | 200°F |

| LS-240-W | 3/4"-16 UNJF-3A | 208/240V | 0.25 | Closed | Red | 180-003 | 0°F | 200°F |

| LS-240A-W | 3/4"-16 UNJF-3A | 208/240V | 0.25 | Open | Red | 180-004 | 0°F | 200°F |

| LS-24 | 1/2" NPT | 24V AC/DC | 0.5 | Closed | Orange | 180-007 | 0°F | 200°F |

| LS-24A | 1/2" NPT | 24V AC/DC | 0.5 | Open | Orange | 180-008 | 0°F | 200°F |

| LS-24-W | 3/4"-16 UNJF-3A | 24V AC/DC | 0.5 | Closed | Orange | 180-007 | 0°F | 200°F |

| LS-24A-W | 3/4"-16 UNJF-3A | 24V AC/DC | 0.5 | Open | Orange | 180-008 | 0°F | 200°F |

| LS-120A-LT | 1/2" NPT | 120V | 0.5 | Open | White or Green | N/A | -40°F | 200°F |

| LS-240A-LT | 1/2" NPT | 208/240V | 0.25 | Open | White or Green | N/A | -40°F | 200°F |

| Catalog Number* | Conn. Size | Voltage | Resistive Rating | Contacts w/ Liquid Present | Wire Color | Repl. Module | Fluid Temp. | |

| 60/80 Hz | AMP | Min | Max | |||||

| LS-120 | 1/2" NPT | 120V | 0.5 | Closed | Yellow | 180-001 | 0°F | 200°F |

| LS-120A | 1/2" NPT | 120V | 0.5 | Open | Yellow | 180-002 | 0°F | 200°F |

| LS-120-W | 3/4"-16 UNJF-3A | 120V | 0.5 | Closed | Yellow | 180-001 | 0°F | 200°F |

| LS-120A-W | 3/4"-16 UNJF-3A | 120V | 0.5 | Open | Yellow | 180-002 | 0°F | 200°F |

| LS-240 | 1/2" NPT | 208/240V | 0.25 | Closed | Red | 180-003 | 0°F | 200°F |

| LS-240A | 1/2" NPT | 208/240V | 0.25 | Open | Red | 180-004 | 0°F | 200°F |

| LS-240-W | 3/4"-16 UNJF-3A | 208/240V | 0.25 | Closed | Red | 180-003 | 0°F | 200°F |

| LS-240A-W | 3/4"-16 UNJF-3A | 208/240V | 0.25 | Open | Red | 180-004 | 0°F | 200°F |

| LS-24 | 1/2" NPT | 24V AC/DC | 0.5 | Closed | Orange | 180-007 | 0°F | 200°F |

| LS-24A | 1/2" NPT | 24V AC/DC | 0.5 | Open | Orange | 180-008 | 0°F | 200°F |

| LS-24-W | 3/4"-16 UNJF-3A | 24V AC/DC | 0.5 | Closed | Orange | 180-007 | 0°F | 200°F |

| LS-24A-W | 3/4"-16 UNJF-3A | 24V AC/DC | 0.5 | Open | Orange | 180-008 | 0°F | 200°F |

| LS-120A-LT | 1/2" NPT | 120V | 0.5 | Open | Yellow | N/A | -40°F | 200°F |

| LS-240A-LT | 1/2" NPT | 208/240V | 0.25 | Open | Red | N/A | -40°F | 200°F |

SPECIFICATIONS

- Inductive rating: 36va pilot duty rated

- Minimum load: 2ma w/o bleed resistor

- Power consumption: 3.5mA AC; 5.5mA DC

- Contact power off: normally open

- Mounting: horizontal only

Optional Junction Box

Switches can be ordered with an optional clip style junction box attached to the switch. When ordering, add the letter “J” to the end of the part number.

(excludes –LT models)

Optical Level Switches

MAXIMUM WORKING PRESSURE: 2500 PSIG

Features

The “LSR Series” Optic Level Switch is part of the Refri-Shield™ line of system monitoring products.

Optical level switches have long been utilized to ensure trouble-free operation and level detection in a wide variety of fluids. With the “LSR Series” level switches, we have utilized fiber optics to isolate the electronics for the smart switch from the sight glass itself, protecting these digital components from extreme temperatures

- Electronics rated to -40°F to 300°F

- Sight-glass body 1-1/8 Nickle plated steel

- Non-invasive liquid sensing

- Serviceable without loss of fluid

- UL listed, file number SA12836

- Switch rated at over 1 million cycles

- Suitable for refrigerants, oils, and other industrial fluids non-corrosive to steel and glass

- Solid-state switching

![]()

| Catalog Number | Conn. Size | Voltage | Resistive Rating | Contacts with Liquid Present | Rept. Module | Fluid Temp | |

| 60/80 Hz | AMP | Min | Max | ||||

| LSR-24 | 1/2" NPT | 24V AC/DC | 0.5 | Closed | 40-3017-24 | -40°F | 300°F |

| LSR-24A | 1/2" NPT | 24V AC/DC | 0.5 | Open | 40-3017-24A | -40°F | 300°F |

SIGHT GLASSES

Features

Sight glasses are installed in vessels to view refrigerant, oil, and other non-corrosive fluids. Our sight glasses are offered in two versions: clear lens and floating ball, with NPT, Rotolock, or SAE connection types.

![]()

| Catalog Number | Thread | Dimensions | |||

| Clear | Floating Ball | A (Hex) | B | C | |

| CL-04 | FL-04 | 1/2" NPT | 0.94" | 0.56" | 0.80" |

| CL-06 | FL-06 | 3/4" NPT | 1.06" | 0.75" | 0.94" |

| CL-08 | FL-08 | 1" NPT | 1.38" | 0.94" | 1.06" |

| CL-10 | FL-10 | 1 1/4" NPT | 1.75" | 1.19" | 1.22" |

| CL-12 | FL-12 | 1 1/2" NPT | 2" | 1.44" | 1.22" |

| CL-16 | FL-16 | 2" NPT | 2.5" | 1.88" | 1.28" |

| - | 45-005K | 1 1/4" Rotolock* | 1.38" | 0.76" | 1.11" |

| - | 45-010K | 1" Rotolock" | 1.13" | 0.50" | 1.15" |

| - | 45-003 | 1 1/16" SAE | 1.25" | 0.75" | 0.96" |

| Catalog Number | Thread | Dimensions | |||

| Clear | Floating Ball | A (Hex) | B | C | |

| CL-04 | FL-04 | 1/2" NPT | 0.94" | 0.56" | 0.80" |

| CL-06 | FL-06 | 3/4" NPT | 1.06" | 0.75" | 0.94" |

| CL-08 | FL-08 | 1" NPT | 1.38" | 0.94" | 1.06" |

| CL-10 | FL-10 | 1 1/4" NPT | 1.75" | 1.19" | 1.22" |

| CL-12 | FL-12 | 1 1/2" NPT | 2" | 1.44" | 1.22" |

| CL-16 | FL-16 | 2" NPT | 2.5" | 1.88" | 1.28" |

| - | 45-005K | 1 1/4" Rotolock* | 1.38" | 0.76" | 1.11" |

| - | 45-010K | 1" Rotolock" | 1.13" | 0.50" | 1.15" |

| - | 45-003 | 1 1/16" SAE | 1.25" | 0.75" | 0.96" |

*Rotolock models include kit with PTFE gasket

Rupture Disk Assemblies

Features

The ‘526’ rupture disk assembly is installed between either a three-way valve or receiver tank and the relief valve to prevent the weeping of refrigerant through the relief valve.

The use of the rupture disk must be in accordance with ASME section VIIII, Division 1, UG 127. The rupture disk setting must not exceed the set pressure of the relief valve. When using a rupture disk in combination with a relief valve, the relief valve discharge must be de-rated by 10%.

There are two 1/8″ NPT connections above the disk. These are used to provide an indication that the disk has ruptured. Pressure gauges and pressure switches can be installed in these ports.

- Brass body, factory sealed, with non-fragmenting disk

- Operating range: -10% / 0%

- ASME Section VIII Division 1 certivied and UD stamped

| Catalog Number* | Pressure Setting |

| 526-235 | 235 psig |

| 526-250 | 250 psig |

| 526-300 | 300 psig |

| 526-350 | 350 psig |

| 526-400 | 400 psig |

| 526-450 | 450 psig |

| 526-500 | 500 psig |

| 526-550 | 550 psig |

| 526-600 | 600 psig |

| 526-650 | 650 psig |

| 526-700 | 700 psig |

Pressure Gauge

W-15 Pressure Gauge

- Pressure range: 0—700 PSIG

- Dial: 1.5″ diameter

- Back connection: 1/8″ NPT